Comparing with the traditional vehicles, electric vehicles (EV) are more environmentally friendly. They reduce the reliance on fossil fuels and reduce greenhouse gas emissions. The electric drive system is the key component of the electric vehicle, which is also the biggest difference between EV and the traditional internal combustion engine-based vehicles. Considering the high power nature of the electric vehicle motor drive, engineers would like to replace the actual motor drive system with a real-time simulator, it will make the testing of high speed, heavy load and fault conditions easily and safely.

Electric drive system HIL

Motor drive system is a typical power electronic system, it contains power electronics devices which switch at several kilohertz. In order to accurately simulate this kind of fast switching system, the small step size (around 1 microsecond) is required. With its FPGA-based small step size simulation technology, StarSim can simulate the entire electric drive system with 1 microsecond step size. In addition, StarSim can directly support models created in the Software such as SimPowerSystems (SimPowerSystems is the trademark of MathWorks) and quickly download them to FPGA target for the real-time simulation. With the StarSim real-time simulator, engineers can test the motor drive controller performance under different working conditions efficiently and effectively, such as different power levels, normal or extreme.

Results

The following figure is a real-time simulation system for the end user. The right side is the real-time simulator of the motor drive system, the left side is the motor controller board to be tested. The motor drive system and the resolver model are simulated on the FPGA, and the resolver is used to provide the motor rotor position information for the controller. The controllers acquires motor currents and resolver signals from the simulator and sends the PWM pulses to the simulator. With these signals, the controller and the simulator form a closed-loop testing system.

Figure:the real-time simulation system platform scene

|  |

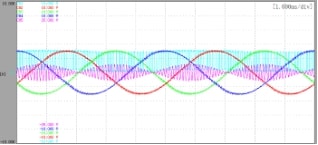

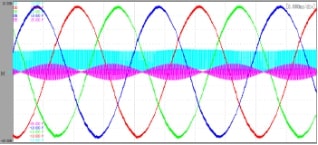

| Signal waveform (Motor:30KW,3000rpm,180Nm) | Signal waveform (Motor:120KW,1000rpm,2400Nm) |

WeChat Official Accounts

Tel

Back to top

Tel

Back to top