"ModelingTech Real-Time Simulator is an HIL simulation platform which is reliable,accuracy and easy to use.It is an important part for our test platform which at the same level as the Electric Power Research Institute .By using this simulator,plenty of problems have been solved and lots of test include L/HVRT test and impedance analysis which are difficult to retest on physical test platforms have been accomplished.Compared with physical test platform,HIL test is more efficient,timeliness have been greatly improved.At the same time,the difficulty of test result storage ,management and analysis got a significantly reduce.What make us more satisfied is the customer service and technical support of ModelingTech.Rapidly response ,patient guidance and several times on-site training,not only solve all the problem during test,increase test efficiency,but also cultivate more excellent HIL simulation engineers,improve the overall strength of our R&D team."

——Chint Power technical research and develop ministry

Project Profile

Shanghai Chint Power Systems is a solar power system solution provider, designing, manufacturing, and supplying high reliability 1kW~2MW PV inverters and power solutions for customers. An international senior management team, experienced and solid research and development resources, advanced component control and design-for-reliability, strong financial support from Chint Group, and inheritance of Chint 35 years' manufacturing experiences and volume, have founded Chint Power System's brand in the field of renewable energy.

As a large renewable energy power generation R & D and production enterprise, Chint Power has a high-quality core technical team, following the technology trend and constantly making breakthroughs. In order to fully verify the grid performance of photovoltaic energy storage products and equipment, the R & D department personnel need to use the HIL simulation platform of the Electric Power Research Institute to complete the task of grid testing again and again.however, each time to do grid testing need to make an appointment in advance and transport the equipment to the Electric Power Research Institute, which will greatly affect the timeliness of the test in the long run. The construction of Chint Power's own HIL simulation laboratory has become a necessary need.After repeated research and testing, ModelingTech HIL simulation platform has been highly recognized by the R&D department in terms of technical level and comprehensive service capability, and thus decided to introduce ModelingTech real-time simulator into Chint power’s HIL simulation experiment platform.

Challenge

The conventional physical inverter power grid tied test exist plenty of problems:

1. High cost of devices such as inductors, capacitors, DC sources and AC sources required in inverter testing, long procurement cycle and much more time for experimental preparation than for test commissioning.

2. Changing the parameters of these devices and equipment is difficult and cost long time on rewiring them.

3. Occupying larger sites and requiring more testers.

4. High-powered products are difficult to find suitable test equipment, and are more dangerous when the software and hardware are not well developed.

eg:Full-power experiments have high site requirements and low efficiency; the grid voltage fault ride-through test environment is difficult to set up and the cost of repeated experiments is high; data recording and data post-processing are cumbersome, and it is difficult to obtain multiple sets of data for repeated experiments.

Solution

Based on the above testing problems faced by the users, ModelingTech proposes a HIL simulation testing solution for them. HIL simulation platform is used to test the model code and access the real controller to the test system, so that the HIL simulation results are closer to the actual, and the closed-loop complete test of the controller is achieved through the rich IO interface.HIL simulation platform is easy to use, and a single engineer can complete all the test contents; and the topology parameters can be quickly modified, so that multiple repetitive tests can be completed in a short time, and the host computer can be used to acquire test result data rapidly. Repetitive testing and analysis is made easy with the companion data post-processing software StarSim Analyzer.

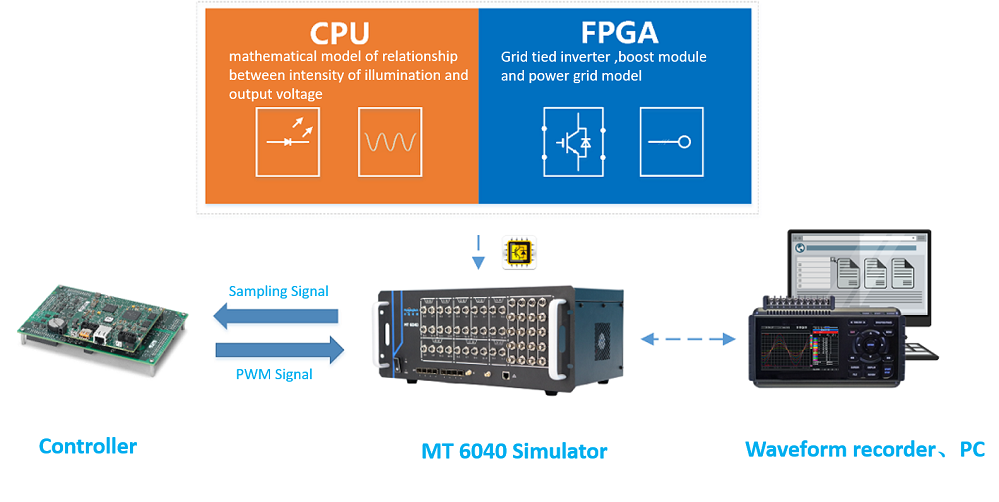

In the user's actual high-power level PV grid tied engineering application, the PV power plant contains a grid-tied inverter and a DC-side boost module, and the switching frequency of the inverter and boost module usually varies in thousands of hertz. The CPU-based simulation scheme, the simulation step size usually ranges from 20 microseconds to 100 microseconds, and it is difficult to accurately distinguish the duty cycle of PWM in the detailed model of power electronic converter simulation in CPU, and the simulation error is large.In PV panels, the impedance analysis test of the converter is needed to obtain the spectrum curve of the transfer function, and the delay time is an important part of the transfer function and more accurate delay time can help to measure more accurate curve results, so small step time simulation is also needed to meet the user's simulation requirements for low delay time.

Except power electronic part, PV power generation system includes mathematical model of relationship between intensity of illumination and output voltage.This part simulation has low requirement of simulation step time,but needs high calculation capability,so that CPU is suits to run this large step model simulation.

Overall consider,ModelingTech provides a simulation scheme based on MT6040,CPU large step combines with FPGA small step simulation.In this scheme,not only simulate power electronic inverter in 1us step,but run the mathematical model which is designed by users in 50~100us on CPU .The whole PV system simulation is perfectly run by combining these two part.

Interview Record▼

Q1:Why choose HIL simulation as the test scheme of controller?

A1:The testing of new products and new controller is usually affected by the hardware development prototyping time factor, resulting in slow progress of software iteration, and it is more difficult to locate the fault problem if the device is damaged during the testing process. Since small-step real time HIL simulation can accurately simulate the switching state of each component, it is very conducive to fault location. When the project is developed, software and hardware can be developed simultaneously without waiting for the development of power hardware, which can significantly speed up the software iteration schedule, reduce R&D costs, and improve efficiency.HIL testing is an advanced debugging method in the power electronics industry. HIL simulation, as a widely recognized new test method, can verify and test controllers efficiently, accurately, and quickly, with one-time investment and long-term benefits.

Q2:Why choose ModelingTech Real-Time simulator?

A2:In the selection stage of purchasing real-time simulator, we researched several mainstream real-time simulator manufacturers at domestic and abroad, including many internationally renowned companies, and invited them to provide equipment for trial comparison .After several rounds of comparison of simulation results, ModelingTech real-time simulator stood out with its unique RonRoff solver.After careful evaluation of a series of items such as applicability, reliability, accuracy and expansion performance of all participating trial products, and comprehensive considerate the departmental budget,ModelingTech real-time simulator met all the standard. Further considering the convenience of subsequent use and technical support, the continuous update support of simulation software functions and other factors, the ModelingTech real-time simulator was finally selected. Our newly purchased MT 6040 ModelingTech real-time simulator has already reached the testing level of mainstream electric research institute in technical performance.

Q3:Are there lots of problems in the use process?

A3:After the purchased equipment arrival,engineers of ModelingTech came to our R&D laboratory for install equipment and operation teaching,and assisted our R&D department engineer to accomplished the preliminary test of a controller. Besides,the host software is suit with usage habits,engineers can operate proficiently after few times simple training.The usual technical support is also in time,helps our R&D engineers find the problems rapidly.Every time the software is updated, professional engineers of ModelingTech will carry out on-site training, and some of our requirements will also get satisfactory replies and improvements.Combined with the data processing and analysis software StarSim analyzer provided by ModelingTech, it can not only meet the observation and analysis of daily test results, but also greatly improve the efficiency of test data analysis.

Q4:What are your expectations for the future use of Modeling Tech real-time simulators?

A4:ModelingTech recently launched a “case switch” feature and StarSim Analyzer software bring us several surprises,and provide some new solution for many problems.Especially “case switch” feature can effectively solve many problems such as high voltage side grid faults simulation and line parameters runtime changing .If we want to complete a large number of HIL simulation test requirements of the company and reduce the workload of test engineers as much as possible, we still look forward to the StarSim auto test function launched by ModelingTech in the future, which will make the HIL simulation test more convenient and efficient; At the same time, we are also looking forward to ModelingTech latest MT 8020 real-time simulator, which can bring super CPU processing capacity and ultra FPGA simulation capacity, and help the simulation and test applications of power grid and power electronic systems such as renewable energy inverters and micro-grids.

WeChat Official Accounts

Tel

Back to top

Tel

Back to top