Application Background

For large-scale grid connections, photovoltaic inverters face immensely complex working conditions. To ensure the normal grid-connected operation of renewable energy generating systems, in the industry's product iteration process, during the actual "R&D—production—testing" steps, R&D and test engineers must make repeated attempts to change control parameters, filter parameters and perform a series of inverter performance tests under varying conditions. Based on the characteristics of hardware-in-the-loop simulation, which supports the construction of arbitrary topology models and is highly accurate, the use of hardware-in-the-loop for photovoltaic grid-connection testing has become the mainstream trend.

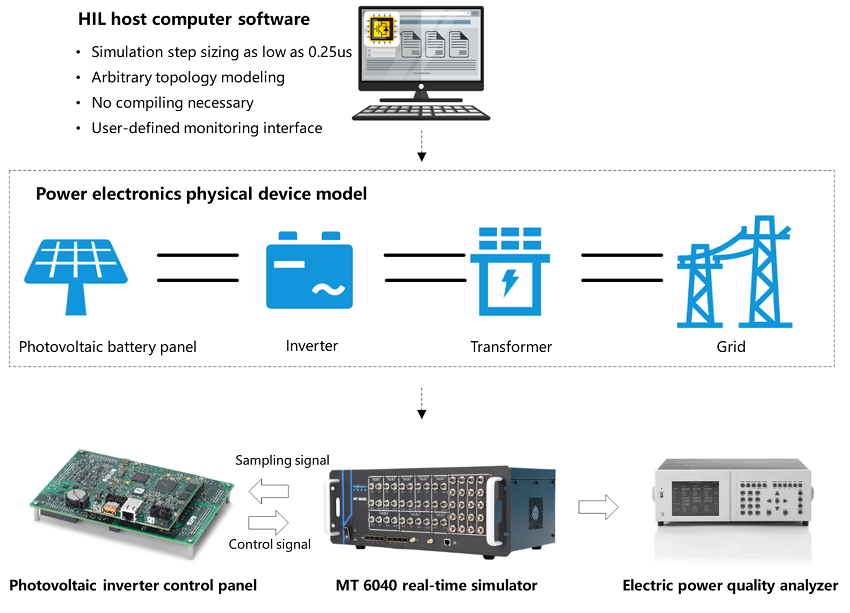

By utilizing ModelingTech's self-developed MT6040 HIL real-time simulator, enterprise engineers are helped to conduct HIL simulation research and testing on photovoltaic inverters as outlined below:

1. Research on the control algorithm and grid-connected performance of the new inverter topology

2. Inverter testing in accordance with grid access test standards

3. Research on power control of a micro-grid system with distributed photoelectric and energy storage systems, as well as its impact on the grid

4. Research on reliability of new control board/control algorithm

Solution

Carry out the simulated operation of a real physical unit, connecting to the physical interface with a real controller, by means of ModelingTech's MT6040 simulator, helping enterprises carry out testing on their independently developed control boards for the purpose of ex-factory testing and control effect verification.

Test Contents

Use of ModelingTech's MT6040 real-time simulation platform can facilitate access to all equipment admittance testing (power electronics), such as HV/LV ride-through testing, anti-islanding protection testing, power factor testing, current harmonic testing, DC component testing, etc.; it can also effectively prevent controller-induced "meltdowns", thus providing enterprises with a safe and cost-effective test platform.

1、HV/LV ride-through

In accordance with “Technical Specification of PV Grid-connected Inverter” (NB/T 32004-2018) and “Technical Requirements for Connecting Photovoltaic Power Station to Power System ”(GB 19964-2012) testing standards, the photovoltaic inverter's responsiveness to transient voltage dips/rises is tested to ensure the photovoltaic inverter can maintain steady grid-connected operation despite grid voltage fluctuation.

2、Frequency disturbance testing

Conduct testing on the inverter’s responsiveness to sudden changes in grid frequency over a period of time, ensuring the photovoltaic inverter is able to remain online.

3、Output electric power quality and efficiency testing

1)Conduct testing on the inverter's output power factor, harmonic distortion rate, DC component, etc., to ensure that such meet grid connection standards.

2)Conduct testing on the inverter’s output efficiency at different filters, so as to improve output filter design.

4、Inverter anti-islanding protection testing

In accordance with the “Golden Sun Certification standard” – “Technical Requirements and Test Methods for Grid-connected PV Inverters” (CGC/GF001:2010), conduct the inverter’s anti-islanding protection testing.

Platform Advantages

● High accuracy

The LC + RonRoff hybrid modeling approach, the first of its kind in China, is adapted for various application scenarios, from low frequency to high frequency conditions. LC modeling is suitable for use at low switching frequencies and RonRoff modeling is utilized at high switching frequencies, without excess switching loss, so that simulation results yielding indications closer to those of a real physical system can be obtained.

● High reliability

Supports an industrial user broad voltage range DI and CAN/RS485/RS-232 communication protocols, and following numerous closed-loop tests, it has become the first choice for many well-known domestic photovoltaic inverter manufacturers for use in R&D and testing!

● Excellent accessibility

It is characterized by compatibility with mainstream modeling simulation software, no need for FPGA programming compilation and abundant IO interfaces, which can greatly improve the real-time operation efficiency when users constantly change the model and modify parameters in the simulation test. Simple aerial plug-in and survey interface is convenient for users to expand and analyze.

WeChat Official Accounts

Tel

Back to top

Tel

Back to top